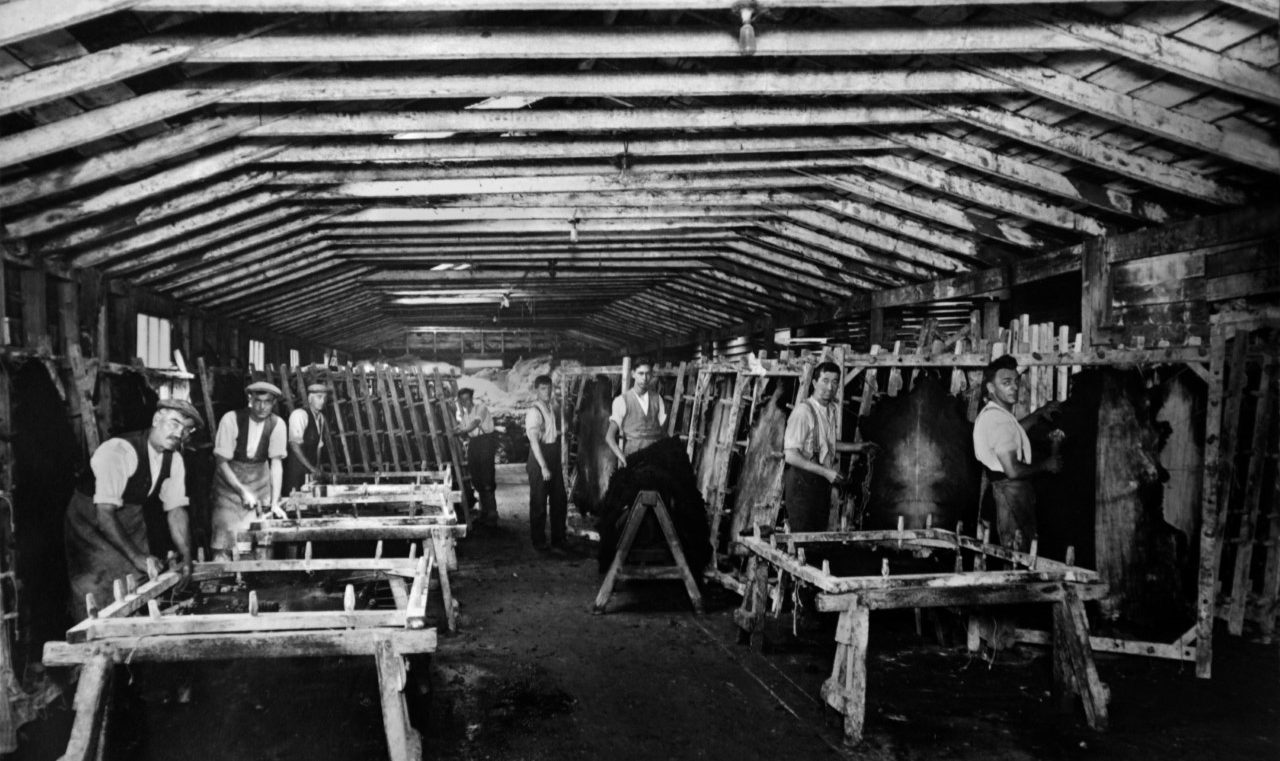

You’d have like a pair of pinchers – but long and with a hammer underneath them – so you’d grab the skin, pull it, put the bobbin in it and knock it in. That stretched them and then they’d dry, and once they were dry they were sorted. Then they come back up and they was either dyed if they were good skins for coats, or they was put in for linings.

[Jim, Morlands]

To take the dry skins off, you had four on the frame. You would take it off, drop it down flat, take off one side, put on two wet skins, turn the frame right over, and then put on, do the other side. When they come out, the actual clips holding it were red hot, so you wore like a glove thing over your hand. You banged off the clips, and took the two dry off. The other person chucked the two wet skins on, and then you stretched them out.

[Jim, Morlands]

Photo: Jim Love

Two guys were ironing them with big steam irons and they had old pennies – when the iron made the seam shiny, they ran them up and down the seams and took it back to a suede finish again.

[Tim, Morlands]

Photo: Alan Hooper

Drywheeling is when the skins have been processed and dried – you start to get off some of the flesh. They’ve already been in the fleshing machines in the yard, so all the fats have been taken off, but then it went into what we call dry wheeling, where the little bits of dried flesh were taken off. You start to create the nap.

[Reg, Morlands]

You’d get other things – I done a giraffe skin once!

[Jim, Morlands]

Baily’s what they called brush-dyed them. You’d mix up your dye with different colours and you’d have them on a metal table and have a bucket behind with the dye in, and you’d brush the dye into the skin and then you had another bucket with acid in it, and that did seal the sealant so that they didn’t come out. And then when you done that, you do them again with clear water – special soft water.

[Jim, Baily’s]

Ironing is where you go into machines, physically held by people, that put in and pull out, so that you get the wool nice and pulled right up tight – nice and shiny and a lovely silky finish.

[Reg, Morlands]