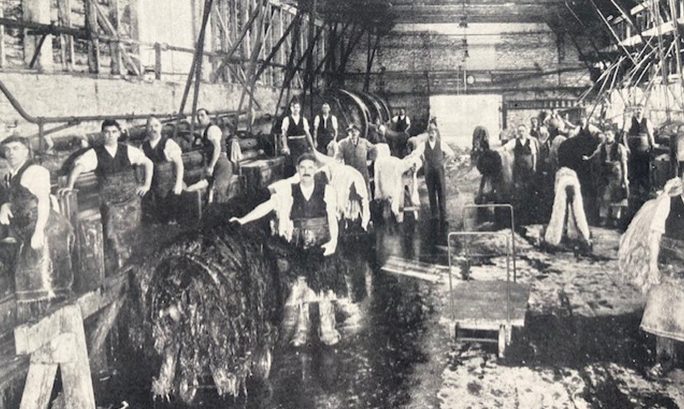

The first morning I was overwhelmed with sights and smells of the yard. Workers walked purposely, intent on carrying out various tasks, everybody was sort of busy and immediate.

[Adrian, Morlands]

Photo: Morlands Archive

No tannery jobs was easy, even up the yard, in the fleshing. I mean it’s all graft, on fleshing machines. Heavy, heavy pelts full of water, you know, with all the wool still on ’em.

You wouldn’t come in there dressed up for work, like, ‘cos it were bloody messy in there.

Up the yard was really messy.

When all the raw skins used to come in – and that’s straight off from the abattoir – they made a hell of a mess.

[Steve and Reg, Morlands]

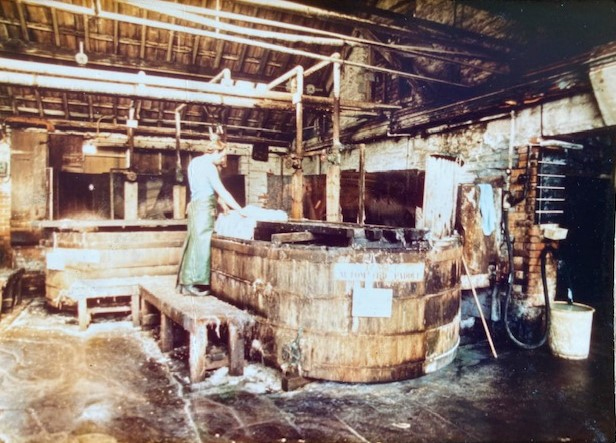

Stoving was the hardest job in the factory, not only was it shift work, the cabinets used to run at 140 degrees and you had ten frames a section, and you had seven different cabinets, these all had two motors on them blowing the heat in. It was always baking hot there.

[Jim, Baily’s]

There were many processes, but eventually they’d get dyed into the big drums, huge big drums, about a thousand skins at a time.

[Steve, Morlands]

Photo: Terry Gulliford

In Baily’s we actually worked inside the stove – you worked inside, you never brought the boards out, you worked in the stove all the time and that was pretty hot and the cabinets, the nailing on was hard work.

[Jim, Baily’s]

Photo: Terry Gulliford